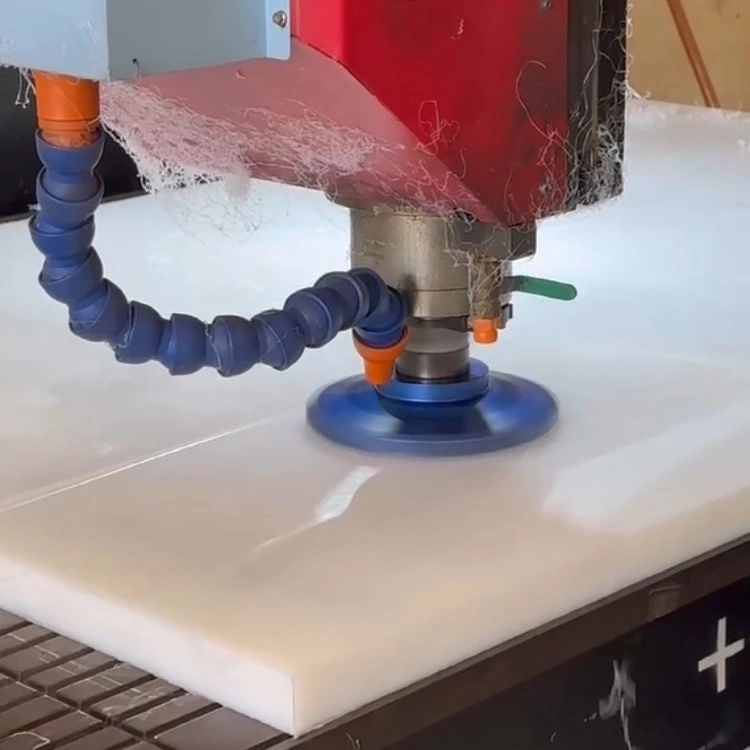

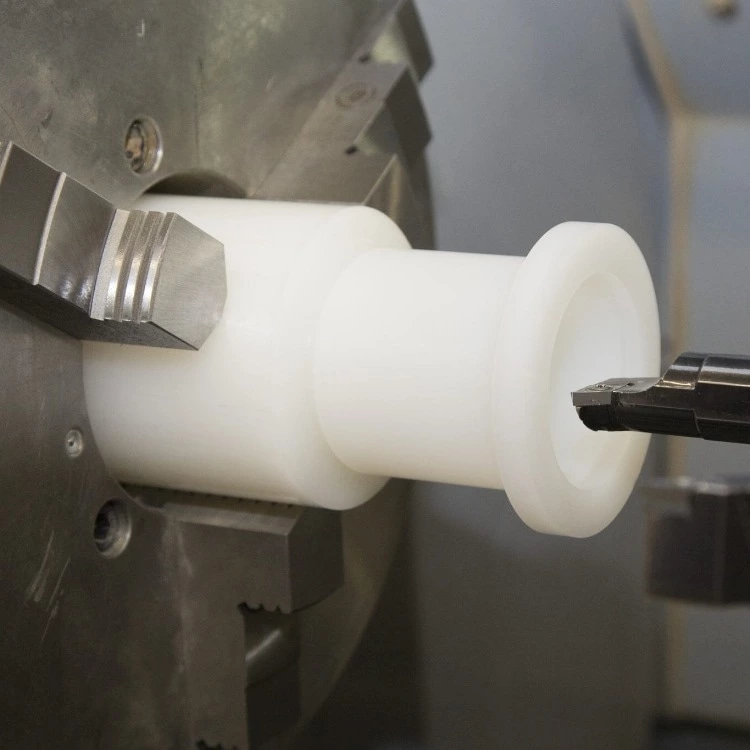

Our CNC machining services are tailored to meet the unique demands of UHMW parts. Whether your project requires simple shapes or complex geometries, we have the capabilities to produce high-precision UHMW components to your exact specifications.

custom blends and additive formulations of UHMW to achieve increased lubricity, UV resistance, antimicrobial properties, decreased coefficient of friction, and a wide variety of other physical and mechanical requirements.

UHMW (Ultra High Molecular Weight Polyethylene) is a common machinable plastic known for durability, versatility and cost-effectiveness as well as abrasion, impact and chemical resistances. FDA compliant natural virgin UHMW is used in applications where high levels of friction are likely to arise including conveyor guard rails, augers and wear strips, belt scrapers, chain guides, and idler rollers. Due to an extremely low coefficient of friction, its inherent lubricity minimizes heat-generating friction that tends to gradually destroy steel parts, and ensures smooth, noiseless operation.

custom blends and additive formulations of UHMW to achieve increased lubricity, UV resistance, antimicrobial properties, decreased coefficient of friction, and a wide variety of other physical and mechanical requirements.

Annealing (stress relief) of machined or semi-finished products is recommended when dimensional stability and freedom of distortion (warping & bowing) of the finished part is desired. Annealing temperatures of 210-310° F (100-160° C) combined with slow cooling will relieve residual stresses, normally caused by non-uniform crystallization during the cooling process. Thicker parts are more subject to residual stresses, since the outside surface cools much more rapidly than the insulated core of the part or billet. Rapid cooling creates an outer shell which restricts shrinking and promotes internal stresses.

In order to properly anneal Uhmwpe the part should be heated in an oven or a liquid bath containing silicone oil or glycerine. Temperatures above 275-280° F (135-138° C), the crystalline melting range of Uhmwpe are preferred. Although heating rate is not important (20° F or 10° C/hr above 175° F or 80° C), cooling rate is critical and care must be taken to slowly reduce the oven or bath temperature at 10° F (5° C) per hour until reaching 150° F (65° C). The part should then be wrapped an insulating blanket to permit slow cooling for 24 hours.

Machined parts with narrow tolerances should only be rough machined prior to stress relief. These parts should be fixtured during the annealing process due to shrinkage. Care should be taken not to overheat the machined surface during final machining to eliminate potential distortion and dimensional change

UHMW (Ultra-High Molecular Weight Polyethylene) offers moderate flexibility with excellent memory properties. While not as flexible as rubber or elastomers, UHMW can flex under load and return to its original shape, making it ideal for applications requiring both impact resistance and some degree of bend without permanent deformation.

Polyethylene 1000 / UHMW Polymer is a Linear Polyethylene with a molecular weight in the range of 3,000,000 to 6,000,000. This value represents the “average molecular weight”.

Therefore, UHMW plastics have a molecular weight average 10 times that of conventional high-density polyethylene resins.

The higher molecular weight is what gives UHMW Polymers a unique combination of characteristics making it more suitable for many applications where lower molecular weight grades fail.

PE1000 is a high-performance polyethylene with product characteristics including a reduction in dust accumulation, high wear resistance and high impact strength.

The long term service temperature range of PE1000 (UHMWPE) Sheet is from 80°C to 130 °C and has a short term maximum service temperature of 150°C

The technique of CNC milling is a kind of computer-controlled milling in which a milling cutter, which is a revolving tool with a cylindrical shape, is used to remove material from a solid substrate to expose a finalized component. Milling machines controlled by a computer may be divided into two primary groups: those with three axes and those with multiple axes. Milling machines with three axes can move the cutting tool or the workpiece in all three linear directions (left to right, back and forth, and up and down), making them ideal for producing designs with less complex elements. Milling machines with four axes or more and multi-axis milling machines are the most effective tools for making plastic components with intricate geometries.

Shengteer, as a leading manufacturer of UHMWPE sheets in China, has nearly 20 years of experience in producing high-quality UHMWPE products. With a commitment to quality and innovation, we are proud to supply UHMWPE sheets that meet the rigorous standards of industries worldwide. Our expertise and advanced manufacturing processes ensure that our UHMWPE sheets deliver outstanding performance, durability, and reliability for even the most challenging applications.

The first step is to simply fill in your information and upload your CAD file. This helps us to create a 3D model of your desired part or prototype.

Within 12 hours, we will provide you with a quote and DFM feedback. This ensures that your project is feasible and provides you with an accurate cost estimate.

Once you have approved the quote and design, we will start production on your CNC prototype or CNC machined parts products.

CNC machined parts or products will be produced within a few days. We ship to you by international express. Please feel free to give us feedback to ensure that they meet your expectations.

Various processing techniques are ready to achieve your specifications. We will offer the best way to suit your part details, tolerances, quantities.

Our technical knowledge and expertise in engineering plastics help you to select the right formulation for your specific application.

Regular sheet, rods, tubes and profiles on stock to support the fast delivery and ultimate convenience for you.

All of our products are available with Low minimum order quantity, no hidden setup charges and fast lead times.

| Thickness(Inch) | Thickness(MM) | Application |

|---|---|---|

| 1/8'' | 3.175mm | Flexible And Thin, Mininal Friction ,High Precision ,Guiding Systems,Rail lining,and Light weight Machinery Components |

| 1/4'' | 6.35mm | Added Durability,No Selfied Flexibility,Mid-load Applications,Light-duty Conveyor Parts,Packaging Machinery,Protective Lining |

| 3/8'' | 9.525mm | Balance Between Thickness and Flexibility ,Agricultural Machinery Linings,Conveyor Chutes,And Sliding Surfaces Inlight Industrial Equipment |

| 1/2'' | 12.7mm | As Standard Industrial Thickness,Used In Heavy-duty Conveyor Systems,Cutting Surfaces,And Machinery Parts |

| 3/4'' | 19mm | Equipment Liners,Protective Guards,Structural Components |

| 1'' | 25.4mm | Loading-Bearing Surfaces,Heavy Equipment Liners,Impact-resistant Barriers,Maxmum Strength In Protection And Longevity |

| Grade | Description | Standard Colours |

|---|---|---|

| Virgin | Standard Uhmwpe | Natural/Black/Green/Colours |

| Anti-Static | Reduces Static Build-up,106_1011 ohms/sq Surface Resistivity | Black |

| Reprocessed | Eco-friendly And Eco Benefit | Black |

| Uv-Stabilized | Formulation For Outdoor Application | Black |

| Flame Retardant | Flame Retardant And Self-Extinguishing | Black |

| Borated Uhmwpe | Boron Loaded For Neutron Shielding Purposes | Black |

| Marine Grade | Low Friction,Excellent Impact Strength And Good Wear Resistance | Black/Yellow/Blue/Colours |

| Lining Grade | Ideal Material For The Bulk Material Handling And Mining Industry | Black/Blue/Grey/Natural |

| Tech | MoS2 Added For Improving Wear Resistance And Sliding Properties | Grey-Black |

| Oil Filled | Reduced Coefficient Of Friction | Grey |

| Glass Filled | Superior Wear Resistance And Dimensional Stability | Blue |

| Metal Detectable | Metal Detectable For Food Processing | Blue |

| Rubber Backed | Rubber Backing Allows The Use Of Adhesives | - |

| COLOR OPTION | APPLICATION |

|---|---|

| Green Uhmw | Agricultural ,Chute Liner,Clear Identification |

| Red Uhmw | Signaling And Alert Zones |

| Yellow Uhmw | Safety Applications,Zone For Clear Marking,Warehouse Markers,Equipment Guards |

| Blue Uhmw | Chemical Resistance,Ideal For Conveyor Belts,Cutting Surfaces,Food Packaging Equipment |

| White Uhmw | Food Grade,Sanitary Environment,Non-Toxic,Easy-to-Clean,Food Medical |

| Black Uhmw | Uv Resistance,Outdoor And Heavy Duty,Construction Liners,Mining Operation |

Finish:Planed/Smooth As Molded

Production Method:Compression Molded

Ultra High Molecular Weight Polyethylene UHMW-PE Products have a well-balanced property profile with a unique combination of wear and corrosion resistance,a low friction surface,and excellent impact strength.the property make UHMW-PE a universally usable material for a wide range of industries and applications

| Technical Data Sheet | |||

|---|---|---|---|

| Physical Properties | Test Standard | Value | Unit |

| Density | ASTM D792 | 0.93 | g/cm3 |

| Water Absorption | ASTM D570 | <0.10 | % |

| Mechanical Properties | Test Standard | Value | Unit |

| Hardness | ASTM D2240 | 62-66 | Shore D |

| Wear Resistance | Sand-Slurry | 100 | - |

| Tensile Strength at Yield 23℃ | ASTM D638 | 3100 | psi |

| Tensile Modulus | ASTM D638 | 100000 | psi |

| Elongation At Break | ASTM D638 | >350 | % |

| Flexural Strength | ASTM D790 | 3500 | psi |

| Compressive Strength | ASTM D695 | 3000 | psi |

| Coefficient Of Friction,Dynamic | - | 0.10-0.22 | - |

| Coefficient Of Friction,Static | - | 0.15-0.20 | - |

| Izod Impact,Notched | ASTM D256 | No Break | Ft-Lb/in |

| Izod Impact Strength | ASTM D4020 | 125 | KJ/M2 |

| Thermal Properties | Test Standard | Value | Unit |

| Service Temperature | - | -200 to 90 | ℃ |

| Melting Point | ASTM D3418 | 130 to 135 | ℃ |

| Vicat Softening Point | ISO 306 | 80 | ℃ |

| Heat Deflection Temperature | ASTM D648 | 43 | ℃ |

| Flammability,UL94 | - | HB | - |

| Electrical Properties | Test Standard | Value | Unit |

| Surface Resistivity | ASTM D257 | >1012 | Ω/cm |

| Volume Resistivity | ASTM D257 | >1015 | Ω/cm |

Size: As the most professional supplier in China, we have the most mold sizes for our customers to choose from. The maximum size is 2M*6M. And we can provide high-quality cutting services to meet the specific needs of different customers for sizes.

Thickness: According to different thickness requirements, We produces the UHMW liner with a thickness of 8mm (Min) and 200mm(Max).

Color: There is a wide range of standard colors available and colors can be customized according to RAL or Pantone color card.

Formulation: UHMW is a high-performance, versatile polymer that can be designed and formulated to meet your industrial needs.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.more details