Performance Comparison of UHMWPE and Other Polymer Materials

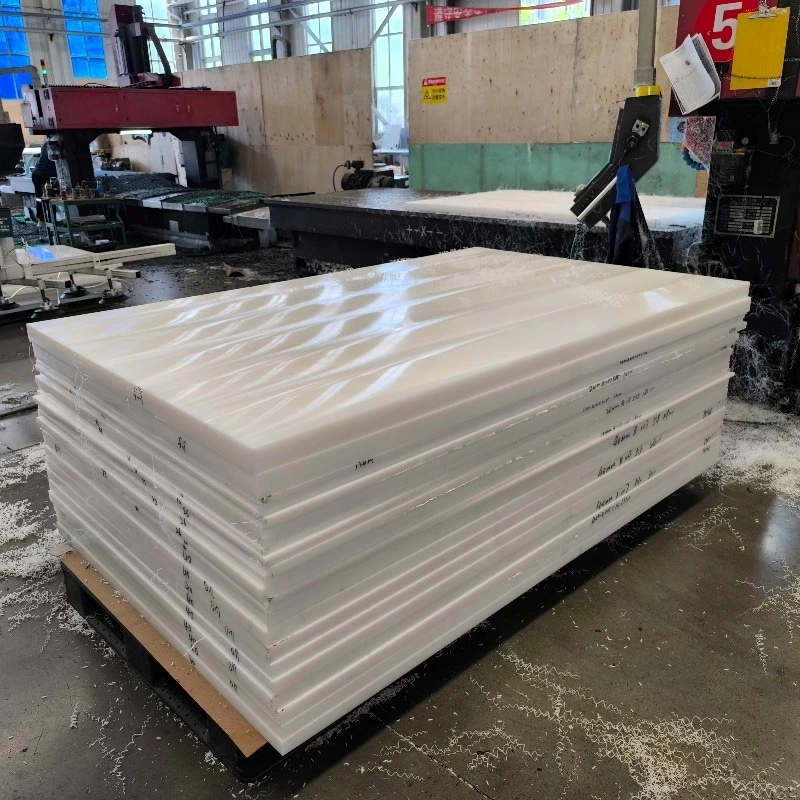

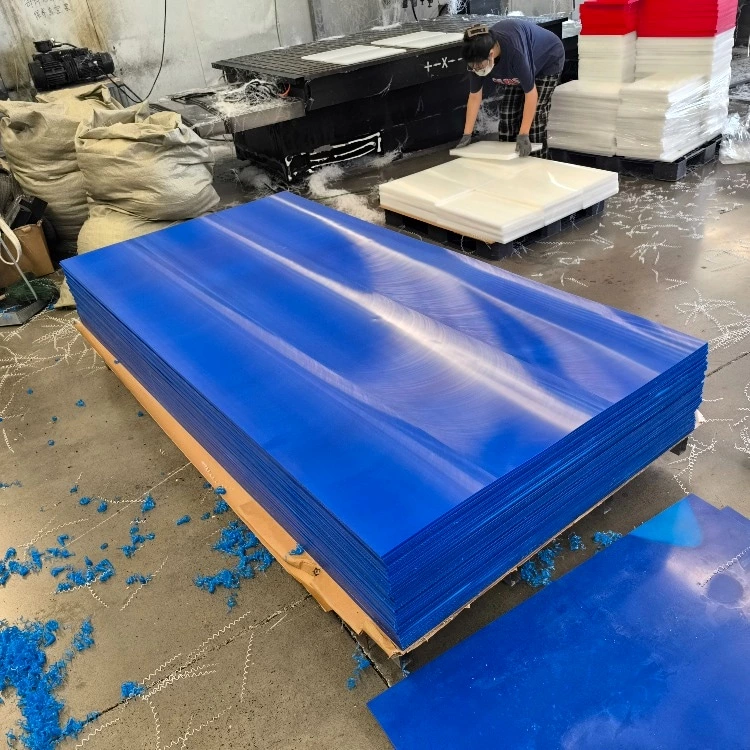

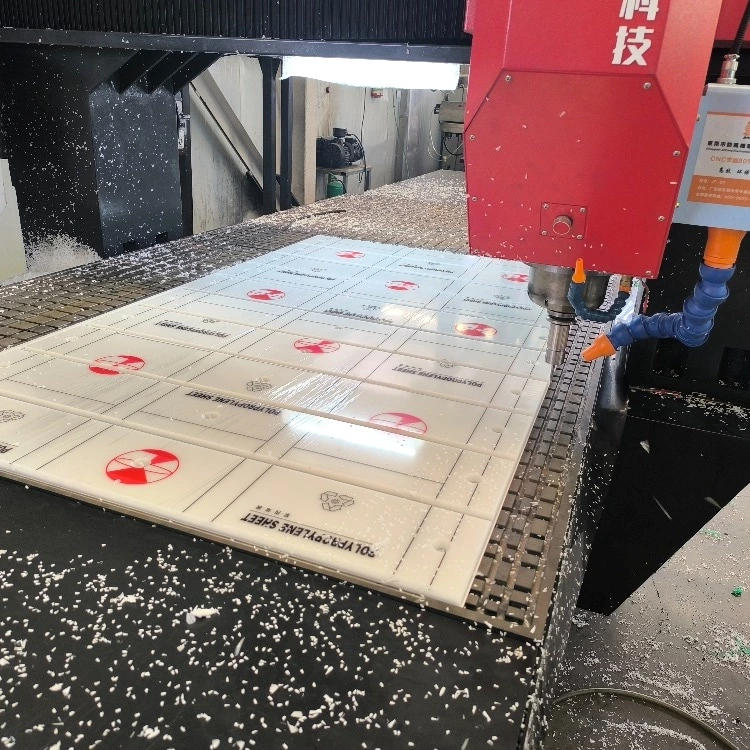

In the field of materials science, polymer materials are widely used in various industries with their unique performance advantages. Ultra-high molecular weight polyethylene (UHMWPE), as an excellent polymer material, has excellent performance in wear resistance, impact resistance, corrosion resistance and other aspects. However, compared with other polymer materials, what unique performance advantages does UHMWPE have? This article will conduct an in-depth discussion of the performance differences between UHMWPE and other polymer materials through comparative analysis.

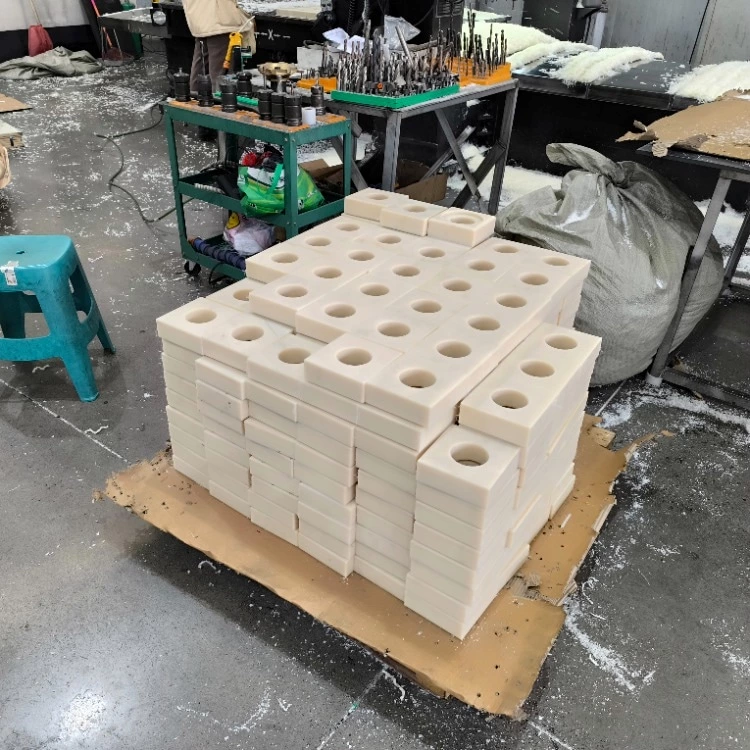

First of all, from the perspective of wear resistance, the wear resistance of UHMWPE is significantly better than that of many other polymer materials. Due to the length and structural characteristics of its polymer chain, UHMWPE has extremely high wear and scratch resistance. This makes it a significant advantage when manufacturing components that are subject to frequent friction and wear, such as conveyor belts, gears, bearings, etc. In contrast, some traditional polymer materials such as nylon and polyester have relatively poor wear resistance and are difficult to meet the requirements for use in high-wear environments.

Secondly, in terms of impact resistance, UHMWPE also shows excellent performance. Due to the flexibility and high toughness of its polymer chains, UHMWPE is able to absorb and disperse impact energy, reducing material cracking and damage when impacted. This gives it a significant advantage when manufacturing parts that need to withstand high impact forces, such as car bumpers, safety helmets, etc. In contrast, some polymer materials are prone to cracking or deformation when impacted, and cannot meet the requirements for use in high-impact environments.

In addition, UHMWPE also performs well in terms of corrosion resistance. It has good chemical stability and can resist erosion by a variety of chemicals, including acids, alkalis, salts, etc. This makes it have broad prospects in applications in chemical industry, medical and other fields. In contrast, some polymer materials are prone to degradation or discoloration when exposed to certain chemicals, affecting their service life and performance stability.

However, although UHMWPE has significant advantages in wear resistance, impact resistance and corrosion resistance, it is not superior to other polymer materials in all properties. For example, in terms of strength and stiffness, some engineering plastics such as polycarbonate (PC), polyimide (PI), etc. may have higher strength and stiffness and are suitable for applications that need to withstand high loads and pressures. In addition, in terms of heat resistance, some special polymer materials such as polyimide and polyphenylene sulfide have higher high temperature resistance and are suitable for applications in high temperature environments.

Therefore, when selecting polymer materials, we need to weigh various performance indicators based on specific application scenarios and usage requirements. As an excellent polymer material, UHMWPE has significant advantages in specific fields, but it does not mean that it is the best choice in all situations. We need to select and match materials according to actual needs to give full play to the performance advantages of various materials.

To sum up, UHMWPE and other polymer materials have their own advantages in performance. Through comparative analysis, we can better understand the performance characteristics and application advantages of UHMWPE, and provide strong support for material selection and application. With the continuous advancement of science and technology and the in-depth development of engineering applications, we believe that more excellent polymer materials will emerge in the future, providing more possibilities for the development of various fields.